About Us

THE GRANNUS ADVANTAGE

- Reduction in natural gas and electricity usage resulting in production cost advantage

- Construction cost per ton at or below plants 3X the capacity

- Effectively no emissions (requires no Title V air or PSD permit and no federal Environmental Impact Study)

- Two-year Construction Schedule, local permitting of 6 to 10 months

- Sizing is ideal for financing and supply of regional syngas, ammonia-based fertilizer, or hydrogen for the fuel cell market

- Requires minimal cooling water and can use air cooled condensers

OUR MISSION

GREENER PROJECTS, MORE SUSTAINABLE FUTURES

As a next generation clean-tech company, Grannus actively seeks a “portfolio shift to green” throughout its development pipeline. Implementing this philosophy means that we work to make each project we undertake greener than what it replaces, thereby doing our part to move the world towards a sustainable future. We aim to do this through process innovation, integration of renewables, combined heat and power, clean energy production, greenhouse gas reduction and sequestration, byproduct utilization, beneficial reuse of waste products, and emission credit creation.

WHAT WE DO

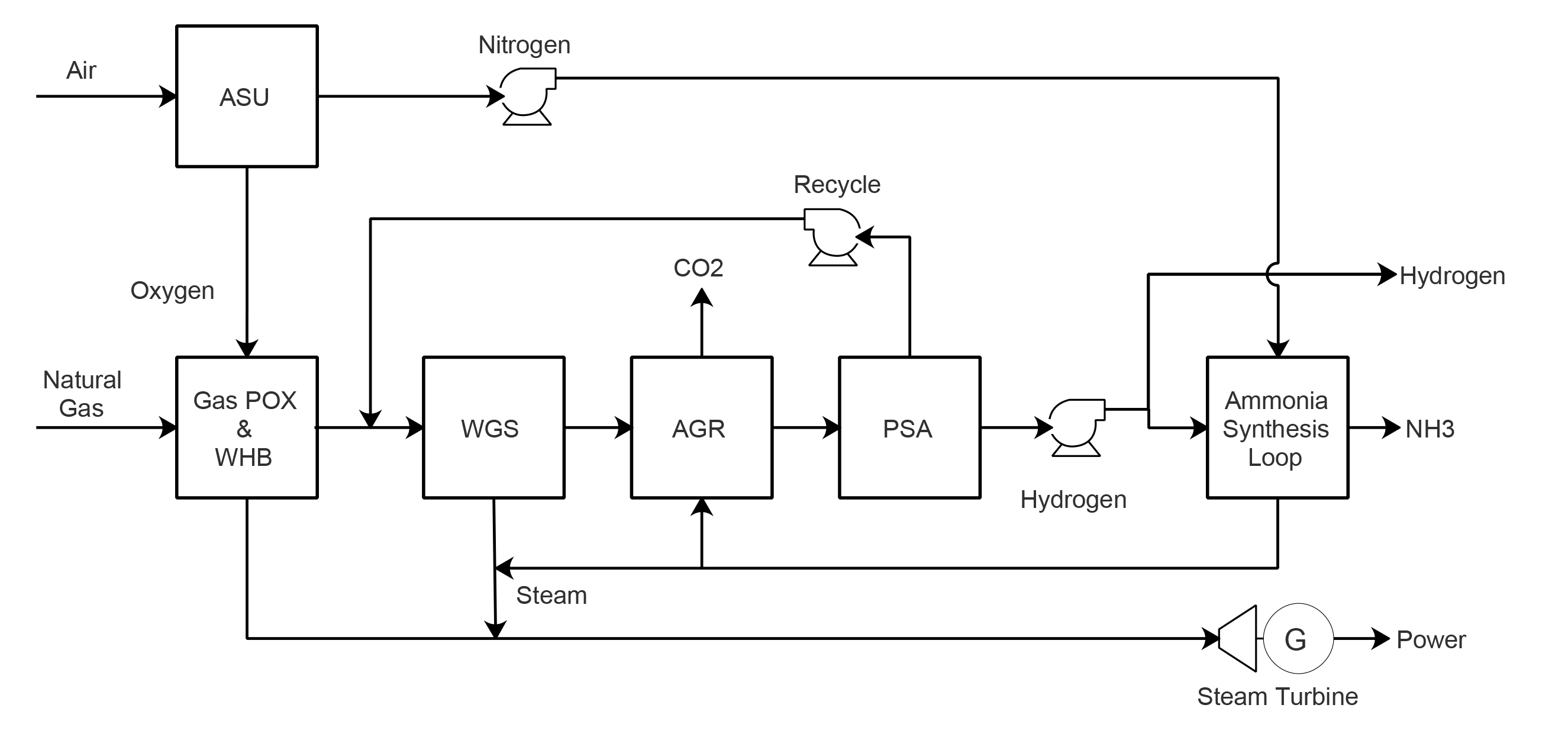

THE GRANNUS PROCESS

Grannus’ technology is used to build near zero emission, exothermic chemical process and powerplants that produce synthetic gas for the manufacture of downstream chemical products along with the cogeneration of clean electric power. Our multi-feedstock technology integrates a partial oxidation gas boiler with the water gas shift process to make high hydrogen synthetic gas. With separation of the nitrogen, hydrogen and carbon dioxide streams, excess power and steam, the building blocks exist to make other chemicals with controlled ratios, such as Haber-Bosch ammonia, Bosch-Meisner urea, or Fischer-Tropsch gas to liquids.

The Grannus process offers many advantages to traditional steam methane reformation production of syngas by utilizing 100% of plant feedstock for the production of syngas combined with strong cogeneration capabilities thereby increasing total plant efficiency. This paradigm shift allows the design and construction of green, near zero-emissions process plants in an otherwise uncertain permitting and political atmosphere; while also competitively reducing the cost to make syngas products locally.